Glass cutting

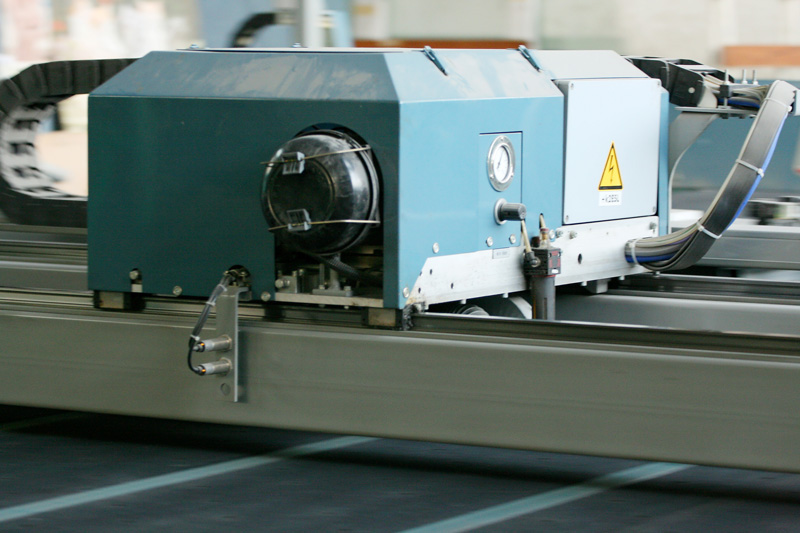

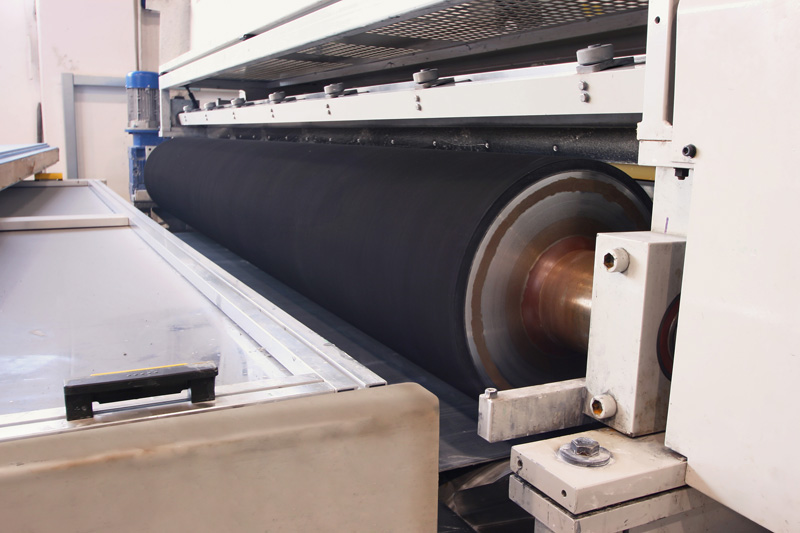

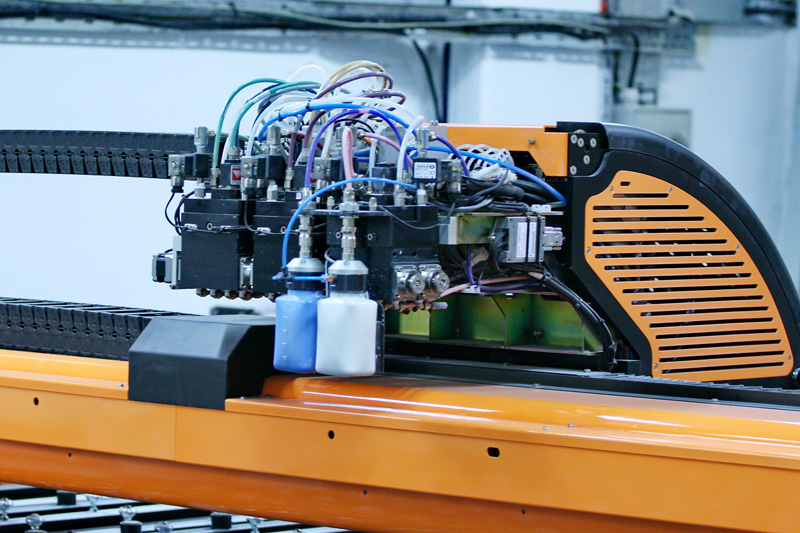

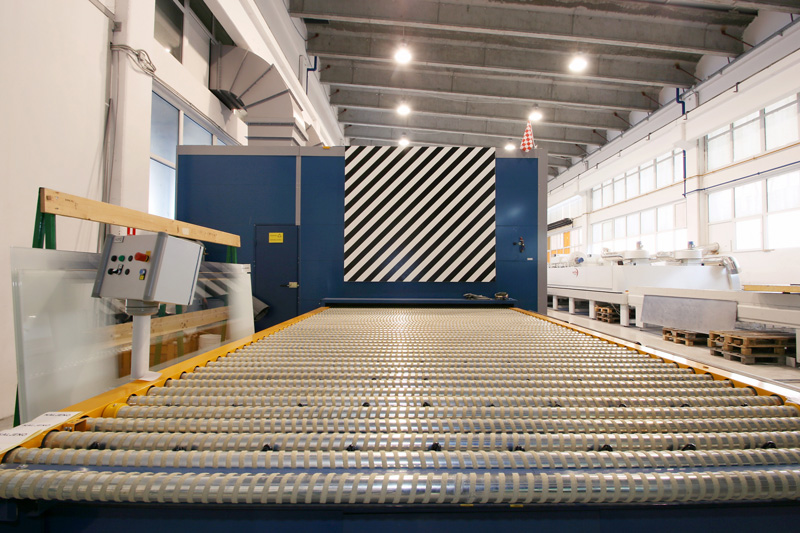

Cutting Glass is the first step in the glass processing. It is done on fully automatic cutting tables, thus achieving high accuracy that is important in the further processing process.

In addition to the automatic cutting table, we have one table for manual cutting of small pieces of glass in our plant. On our automatic table it is possible to cut glass of 3-19 mm thick.

In addition to a single glass, it is possible to cut a multi-bonded glass of the largest thickness of 20mm.

The largest glass cutting dimension is 6000x3210mm

Manufacturer: LISEC - Austria